How to use equipment for agricultural fertilizers and their types

Fertilizer or Manure speaders

machine Manure spreaders

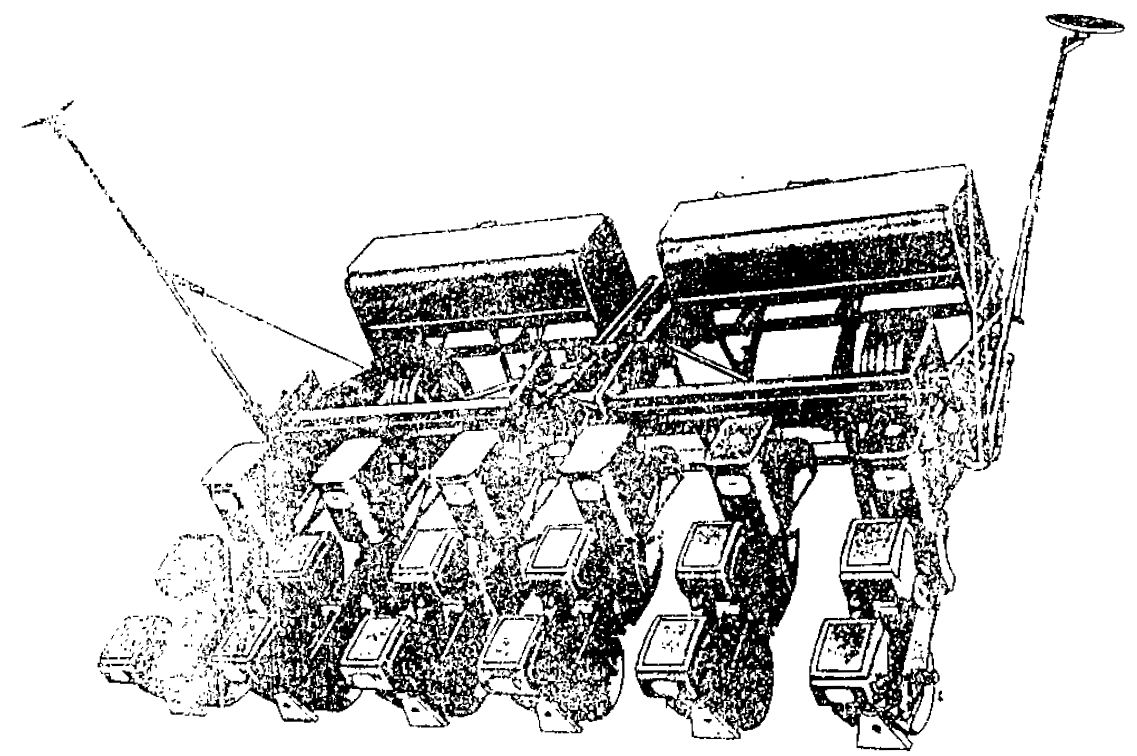

These machines are similar to farming machines. They may be fertilizer machines, or machines that place fertilizer in rows beside plants. These machines may be specific to fertilization or are machines that cultivate and fertilize.

Tests are carried out on different types of machines, different conditions for soil and weather conditions as well as different types of fertilizers and crops. Laboratory tests and field tests are conducted. Generally, fertilization machines can be divided into:

First: Chemical fertilizer distribution machines:

1. Manure spreaders may be ground machines or aircraft.

2- Fertilizer underlining machines.

3. Combined units such as fertilizer and grain underline machine.

4 - Special combinations for the distribution of manure in agriculture machines in rows.

5. Fertilizer spraying machines are similar to those used to spray pesticides and are used to distribute liquid manure.

Centrifugal fertilizer is similar to centrifugal cultivation machines. The amount of fertilizer (sludge or seed) is controlled by controlling the distribution by means of a disk or two rotary disks. Some centrifuges can be used for centrifugation in agriculture or fertilization. Fertilizer and lime trailers are frequently used, and aircraft are used for manure dispersion in vast areas with hills or difficult terrain, such as flooded rice farms.

And machines that distribute fertilizer in lines or lines resembling agricultural machines where the fertilizer falls on the equipment to adjust the fertilizer feed distributed at regular intervals usually about 15 cm on the total length of the fertilizer tank and this equipment suitable for the distribution of fertilizers or lime. Some of them have holes to open grooves to place manure in slices under the surface of the soil and can be used to put fertilizer on the side of plants in the case of large distances between plants.

The main factor for the evaluation of these machines is the regularity of distribution over a wide range of conditions, ie, the performance of the feeder in different conditions and the rate of disposal with the forward speeds of the machine. The rate of disposal shall not be affected by the filling of the hopper by fertilizer or the soil inclination. It was better as the machine should be easy to control, maintain and clean and its ores are the kind that resists chemical reactions with fertilizers.

Fertilizer is collected from each part and weighed. These weights are attributed to the total. The mean, the highest value and the least value of the distribution are estimated. The difference between the lowest value The higher the small value, the better the machine is in performance, and the distribution width of the machine as well as the required interference area, especially in the prose machines, is estimated.

Second: Municipal organic fertilizer distribution machines:

1. Machines operated by the rear tractor shaft.

2. Earth-powered machines.

These machines distribute organic fertilizer quickly and regularly and are generally composed of the box and the transport device that slides over the floor of the box, which is a track or mat and the third part of these machines are found in the back of the machine to break the manure and push it back, and the distribution device disperses and distribution of fertilizer at the back of the machine To the right and left, so that the compost is spread over a wider strip than the box of the machine. In general, the machines that are managed by the rear management shaft are preferred. The required distribution rate can be given. Machines that are run with earth wheels. The tractor wheels tighten the load as well as give the power needed to manage the machine wheels. Therefore, there is a large load on the wheels of the tractor, which leads to sliding, especially in the disintegrated or wetland.

Evaluations factors fertilizers machine

1. Regular distribution of manure over a wide range of conditions. The regularity of the distribution of compost units in segments depends mainly on the performance of feeders. Whereas incidental propagation is the determining factor for assessing the performance of centrifugal effluents.

2- Extent of the distribution of manure and the extent of the rate of disposition with the front speed of the machine.

3 - Extent of independence of the rate of disposal of high manure in the hopper and land tendencies.

4 - the ease of the jaw and installation of the feeders to complete the cleaning.

5 - the extent of resistance to parts of the machine to corrode as many fertilizers are working to eat parts of the machine.

Types of metering devices

Second: Municipal organic fertilizer distribution machines:

1. Machines operated by the rear tractor shaft.

2. Earth-powered machines.

These machines distribute organic fertilizer quickly and regularly and are generally composed of the box and the transport device that slides over the floor of the box, which is a track or mat and the third part of these machines are found in the back of the machine to break the manure and push it back, and the distribution device disperses and distribution of fertilizer at the back of the machine To the right and left, so that the compost is spread over a wider strip than the box of the machine. In general, the machines that are managed by the rear management shaft are preferred. The required distribution rate can be given. Machines that are run with earth wheels. The tractor wheels tighten the load as well as give the power needed to manage the machine wheels. Therefore, there is a large load on the wheels of the tractor, which leads to sliding, especially in the disintegrated or wetland.

Evaluations factors fertilizers machine

1. Regular distribution of manure over a wide range of conditions. The regularity of the distribution of compost units in segments depends mainly on the performance of feeders. Whereas incidental propagation is the determining factor for assessing the performance of centrifugal effluents.

2- Extent of the distribution of manure and the extent of the rate of disposition with the front speed of the machine.

3 - Extent of independence of the rate of disposal of high manure in the hopper and land tendencies.

4 - the ease of the jaw and installation of the feeders to complete the cleaning.

5 - the extent of resistance to parts of the machine to corrode as many fertilizers are working to eat parts of the machine.

Types of metering devices

The most important parts that determine the quality of the performance of the fertilizing machine are feeders. There are many types of these machines, including the following:

1-Star- Wheel feed

This feeder is located under the hopper in the form of an astral wheel and each wheel carries a certain amount of compost through a feeder slot. The portable fertilizer between the feeding wheel teeth falls into the feeding tubes by gravity and scraps the rest of the compost from the surface of the wheel. The rate of action is controlled by raising or lowering a gate above the wheel. As well as the speed of the wheel. Each wheel is run by a set of vertical gears, from the feeding column under the hopper, and there are means of protection from the fossil fertilizers of these star wheels.

2-Rotating bottom metering device

The base of the manure bucket has a horizontal rotary base and the fertilizer disposal rate is controlled by a gate set on a side exit.

3-Metering device with auger

There are two types of these devices, a type that revolves in a pipe diameter larger than the hoof by about 1.3 cm and another type where the vine is free where the fertilizer enters the tube of the vine from the top and then moves to a short distance within it to exit the exits located in the corners. The tube is at the base of the tank and can be raised. There are many openings on this tube to give several exits to use for row crops or prose and the rate of action is adjusted by changing the speed of the barrel.

4-Vertical rotor metering device

Consists of vertical wheels for feeding on their edges, and these feeding wheels are distributed along the tank and rotated through a single column. The width of the wheel ranges from 6 mm to 32 mm where it is used for different feeding rates. The rate of action adjusts the speed of the rotary column that drives the vertical wheels.

5- Belt metering device

These devices are used for high rate of conduct. Where the walk removes the manure from the bottom of the tank and makes the belts of steel or rubber and adjust the rate of disposal through a gate can be controlled. The disposition may be divided into two or more birds when fertilizing row crops or vegetables.

Factors affecting discharge rates and uniformity of distribution for fertilizer deills

The rate of conduct and regularity of manure distribution from fertilization machines is affected by several factors including:

1. Feeder type.

2. Humidity of compost and relative humidity at which storage was carried out.

3 - the form and size of the granules and the density of real and virtual.

4. The susceptibility of manure to quarantine.

5- Comfort angle of fertilizer.

6 - the fullness of the machine reservoir.

7- The extent of the earth's tendencies that God destroys.

8. Rotation speed of feed column connected to the feeder.

9 - the extent of vibration of the machine and concussion parts and not to adjust the tendencies of the distribution pipes.

It has been found that the ease of manure or so-called fertilizer flow is inversely proportional to the comfort angle and that fertilizers with a resting angle greater than 55 degrees can not feed well with most types of machines. The tilting of a machine with a star-shaped feeder or a rotary base of the tank by 10 degrees in the direction of the outlet has increased the rate of disposal by 11 to 21% due to the increased gravity effect. While the tilt in the opposite direction has reduced the behavior compared to the behavior at the horizontal position of the machine ..

Experiments have shown that increased speed has reduced the rate of disposition of different types of fertilizers but the lack of rate of disposal has varied from fertilizer to fertilizer according to fertilizer specifications. It was found that the maximum rate of differences from the mean was only from 5 to 14% for fertilizers with 35 ° comfort angle.

While the fertilizer with a large comfort angle is irregular regardless of the type of feeder because of the lack of flow of manure freely and found wide differences in disposal rates out of all feeders used with composting with a comfort angle of 54 degrees and there may be difference in the rate The behavior of the feeding units, which therefore affect the uniformity of the distribution between the units of the machine in a vertical direction on the process of the machine and showed some experiments that these differences ranged between 6% and 31% depending on the type of fertilizer and the type of feeder.

Factors affecting discharge rates and uniformity of distribution for centrifugal brodcasters

The rate of disposition and uniformity of distribution in these machines is affected by the outer diameter of the fan disk, the feather angle for the radius, the country distance for which the compost is fed, the rotational velocity of the disc and the friction coefficient between fertilizer and feathers. By changing the shape or angle of the feathers on the fan disc, this distribution can be improved. The rate of disposition and uniformity of distribution is influenced by the characteristics of compost, where the size, density and shape of the grains affect the horizontal distance that the granules move. Large, high-density particles carry a horizontal distance beyond small particles and dry mix components of different particles that have different distribution patterns if the particles have different natural properties. Winds also affect the carrying distance of particles and thus affect the uniformity of fertilizer distribution.

There is usually a distribution pattern for each machine that may have a flat, pyramid, elliptical or convex top, and until there is regularity in the distribution, the amount of interference to the machine's working machines should determine the optimal interference of each machine and each type of fertilizer until there is a symmetrical distribution in each Distributed fertilizer field.

It is worth mentioning that manure can be spread by aircraft in vast areas, mountainous terrain or rice-filled rice plantations. Wing aircraft as well as helicopters. There are many factors that affect the regularity of distribution.

No comments