how to Used metering device for agriculture

Types of metering device

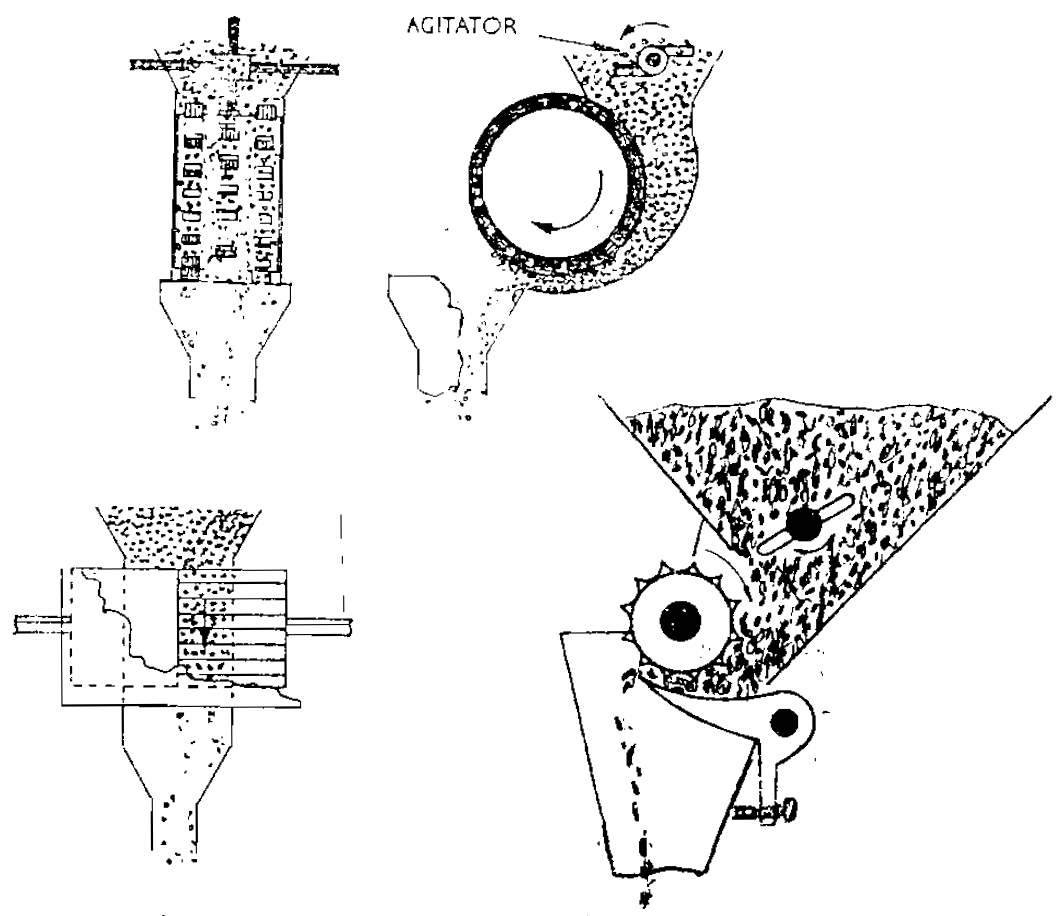

first - flow seed metering devices

There are many types of feeders and most of these species are continuous seed feeders, which provide some continuity in seed flow. The feeders are used with double-sided and double-helical feeders and with line machines, but are mainly used for grain-laying operations and generally prefer Corrugated cylinders are fed to dual-streamed species when small seeds are traded. Dual-feed domestic feeders may be used with large and small seeds. Depending on the type of the device, either move the corrugated cylinder centrally to change the amount of seeds exposed in the seed box or change the ratio of speed between the wheel and the feed column.

Sowing machines usually have a fixed slot feeder. The feeding rate is controlled by selecting the appropriate opening size and preventing the accumulation of seeds over the hole and reducing the effect of grain height in the box on the flow rate. This machine provides many discs containing a wide range of different holes to suit the size of different seeds and the required feeding rate.

Second: Devices for metering single seeds

There are many of these devices where there are many crops and vegetables are cultivated in this way and these devices have the cells distributed to a moving member or a specific organization to capture seeds from the reservoir and paid in the seed tubes single form and generally can be divided into the following types:

1. Horizontal disks with cells:

Horizontal-cell disks are common examples of single-feed devices. There are two types of these disks. Either the cells are on the periphery of the disk or are in the form of circular or oval holes that are also distributed around its perimeter. The fixed loop on the perimeter of the disc is part of the cell wall and therefore it must be closed to ensure satisfactory performance. These tablets are exchanged according to the method of cultivation of different crops. Many of these tablets are available to meet the needs of many different types and sizes of seeds.

2 - slanted discs with cells:

In which the seed disk is tilted and contains mugs or surrounding cells passing through the seeds box to raise the seeds during the rotation of the disc and drop them in the seed tubes and treat the seeds here more gently than horizontal disks where there is no way to push the seeds into the tubes. The feeding unit is a disc with a number of cells suitable for different sizes of small vegetable seeds. Discs and surrounding rings are precisely made to give cells of a regular size to feed accuracy.

3 - vertical disks with cells

Feeders with rotating rotary disks are often used for precision cultivation and some units may not have a seed tube and rotary disks are placed as close as possible to the soil where the seeds fall directly into the groove.

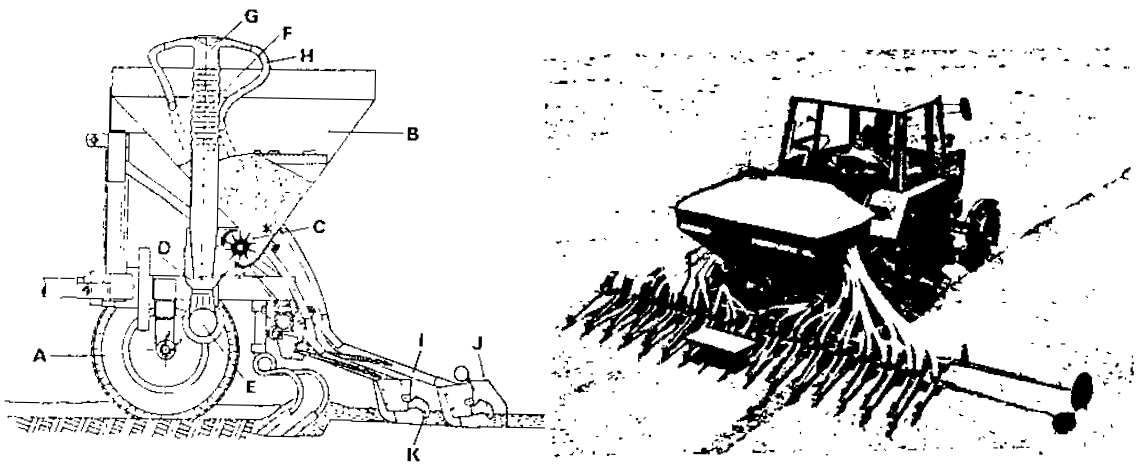

4. Feeding device with walk:

It is used for precise underlining and contains a path with cells of a size that fits the seed shape. The seeds enter the reservoir and the seeds remain at a certain level. It moves in the direction of the clock while another disc rotates in a counter direction. It is called a seed repellent where the excess seed is stored and thus the presence of one seed in each cell. The seeds move with their cells on the base until they fall off the walk when the seed repels.

5. The finger-feeding device:

These species can accommodate normal variations in seed size and shape as in some seed varieties. It is a group of finger-loaded with the beads on the diameter of a diagonal spindle, and the fingers grasp one or more seeds as they pass through the seed tank. All the seeds are released except one when each finger passes on two of the nests near the top of the hard disk, On a slot in the disk that drives the seeds to one of the cells on the adjacent rotating wheel. The rotary wheel runs the seeds into the groove.

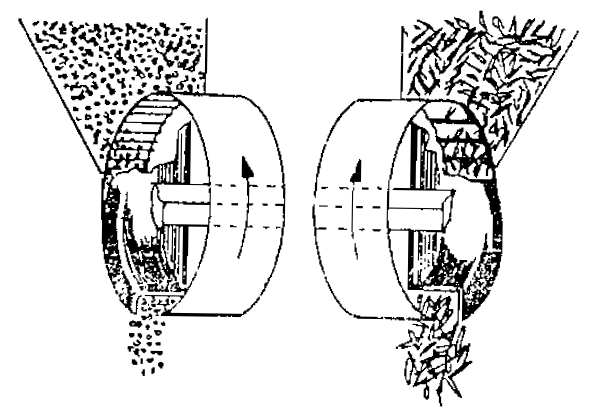

6. Pneumatic feeders

The air-pruning system contains a cylinder that rotates through the earth wheel of the machine and has rows of perforated pockets. Equal to the number of lines of cultivation of the machine. The seeds drop from the tank by gravity into the cylinder. With a fan rotating through the rear management shaft, air is pushed into the cylinder and the tank presses about 4 kPa and the air leaks through the perforated pockets, pushing the seeds with it. The pressure difference is that the seed is placed inside the pockets as the cylinder rotates upwards to pass a fixed brush near the top of the dimensions ie any excess seeds. There is a wheel to cut the air stream at the top of the cylinder and it immediately locks the hole, causing the fall of the seed to the pipes of the seed pipes. A different cylinder is used for each type of seed.

The air feeding is used in one-row farming machines using small fans to give air pressure in the feeding chamber and to hold the seeds held on the openings in the rotary seed pockets to the top and leave the seeds in the seed tubes when the pockets pass through a barrier that cuts the internal air pressure and uses different rotary discs Seeds and planting rate required.

7. Air-discharge feeders

Most of these devices consist of a central vacuum pump and valves for each seed hole and a tight seal between the seed tubes and the rotor capture device. There is a system consisting of camshafts and turbines for the necessary discharge events on time to attract seed from the seed box. The performance of vacuum feeders is effective even with small seeds with irregular shapes but expensive machines.

Third: Collected feedings

Seed tablets containing large cells are used and allowed to be filled with a variety of seeds, but often a seed stump occurs especially at high forward speeds. The seeds may be dispersed as a result of the delay in their flow from the disk cells. More precise distances between the furrow and a close number of seeds can be obtained in one jar using the seed transfer wheel. This wheel collects the desired number of seeds for rotation while acting from the seed disk and then moves them close to the bottom of the groove. Low speed for the earth. Another type of combined feeder is the frequency valve. However, the rotary valves are more suitable for high-speed operations. The valve is used mainly for the cultivation of maize in intermittent feeding and can also be used for complex pruning.

No comments