how to used farm moldboard plows

Moldboard plows

There are two types of plows: one-way plows, two-way plows and one-way plows are the most common for their simplicity. The two-way plow has two sets of contrasting wheels which can be used as a choice. In this plows, all grooves can be rotated on the same side of the field using the right hands in the direction of the left and the left in the case of return. These plows consist of the body, the stalk, the frame and the wheels. The heart or fragmentation of the education and the basic function of the body of the plow is the cut groove slice and the fragmentation and heart of the groove harvested and all the plows, which currently have a normal weapon to be disposed of in the case of consumption. These weapons are available in various forms. It is made with a specific length and shape and is fixed by rivet screws. The body of the plow must have head clearance and side grooves for easy preservation of the depth and width of the desired pieces.

1 - Moldbord

The hammers are usually made of low carbon steel in the center and the outer layer of the high carbon steel castor. After thermal treatment, the outer layers become solid and have soft surfaces with high corrosion resistance in most of the soil. As a result of its low carbon content, the middle layer is affected by the thermal process. It is therefore soft and gives an ability to absorb shocks. Low carbonization can be made in its carbon content to obtain solid surfaces.

Many different types of hammers are developed. Common species include general purpose objects, root floor beds, plant residues, muddy wetlands, deep plowing and black land. The root-filled land has a low, long, gradual curvature and a spiral shape that allows the kidney of the groove to be harvested with the least amount of cracking, thus leading to full vegetation coverage. The short and wide body with a sudden bending at the end leads to more fragmentation compared to the burner Other. The body of the general purpose is the middle between these two types of the extremes of eternity. It is fit for a wide range of conditions and conditions. The black earth has a relatively small surface and a shape that helps to slide into those heavy lands. The shape of the plow can be distinguished by measuring the horizontal coordinates of the equator at equal vertical distances and drawing the results at the horizontal level of the body

There are several types of disk knives and used disk knives to help cut the groove wall, as well as to cut plants on the surface of the soil, which may accumulate in front of the weapon, or on the plow frame and thus impede its performance. Knives with flat surfaces are used in fields free of strong plant residues.

The disk-shaped disk with the curved edge and the other with the corrugated edge work well in the soil where the plant remains are abundant. The disk's Nirvana will be found directly above the side of the weapon or 1-2 centimeters in length. The large diameter disk drive works easily in the case of intensive crop residues, which are better than small diameter Nirvana, but penetrate the solid earth less.

3. Weapon: Share

The forces needed to tighten the plow-Draft of plows

The strength of tensile strength is influenced by many factors such as soil type and wetness, speed of tillage, plow shape, unit and shape of arms, depth of tillage, cut groove width, types of accessories, method of control of plow and its components, and main factors contributing to changes in tensile strength The type and condition of the soil The specific tensile values range from 1.4 to 2.0 N / cm2 in sandy soil and up to 14 N / cm2 in heavy clay land. While 4 to 8 Newton / square centimeter of clay clay and soil moisture content are important factors affecting tensile strength and performance, as dry soil requires high capacity. It was found that the increase in humidity from 9.1 to 11.7% reduction of the qualitative tensile in soft sandy soil from 15 to 35%. The degree of clamping, pre-soil treatments and the type of crop residues affect the qualitative tension.

Many experiments have shown that the specific strain of plowing usually decreases as the depth increases to an optimal ratio from the depth of tillage to plowing and then the qualitative tensile increases as the depth increases. The shortfall that occurs at the beginning is logical because the total force needed to cut the bottom of the groove does not depend on depth. The increase in the tensile strength after optimum depth is due to the increase in soil accumulation due to the deep depth on the surface of the Hammers.

How to used the earth backhoe and its types

Types of earth backhoe

There are many machines of the earth, where there are types that raise the soil a little depth and other types that deepen in the soil and some of the soil turns the heart completely and some of the fragmentation and softening of the soil. Some of these machines resist dense in-depth weeds and some can not work under such conditions. In general, equipment for land cultivation can be divided into the following:

1 - Plows Excavator: Chisel plows

There are many types of plows, depending on how they are connected to the tractor, according to the width of the plow, the distance between the bronchial and the bronchial, whether they are flexible or solid, and the type and dimensions of the arms.

2. Moldboard and disk plows

These plows are the core of the soil and differ in the shape of the weapon and how it is connected to the tractor and the width and number of weapons. There are two main types of plows, plows and plows.

3-Rotary plows

These plows stir and soften the soil in a small depth, including self and other types of tractor. These plows differ in the type of weapons. The weapons may be solid or flexible and may be large or small. These plows are often used in the process of hoeing.

4- Harrows:

There are many types of combs and may be disk combs or combs with solid teeth or combs with flexible teeth and in each of these combs there are many types that differ in the form of weapons and display work and distance between teeth or weapons and the number of rows of weapons and so on.

5. Plows under soil: Subsoilers

These plows are sometimes used in the presence of underground layers under the surface of the soil. These types of plows differ in the number of weapons, in the depth of the weapons and in other specifications.

6-Ditchers

These beads are used to make lines before planting the earth in some crops such as cotton and maize. These vesicles differ in the width of the work, in the distance between the vesicles and in the way the angles and distances of the vesicles are shaped.

7 - Other types of plows:

There are other types of seed graft machines such as Vibrator. These types of weapons include the plows of one of the previous types, but the weapons have a vibratory movement. These plows differ in the speed of the vibration, the direction and pattern of the vibration movement and the shape of the weapon. Other types of plows have vertical axes.

how used farm straw pressing machine (feed)

Straw pressing machines (feed)

This type of machinery takes hay or green feed after drying from the surface of the soil, and in the form of rectangular or circular bales and tie it to the thread.

There are two kinds of feed presses:

Frequency Feeding Machine

Circular Feeding Machine

First: Frequency Feeding Machine:

This machine compresses the feed in rectangular bales 90 cm long and 40 cm width, making it easy to process and transport, which consists of:

1 - Pickup device:

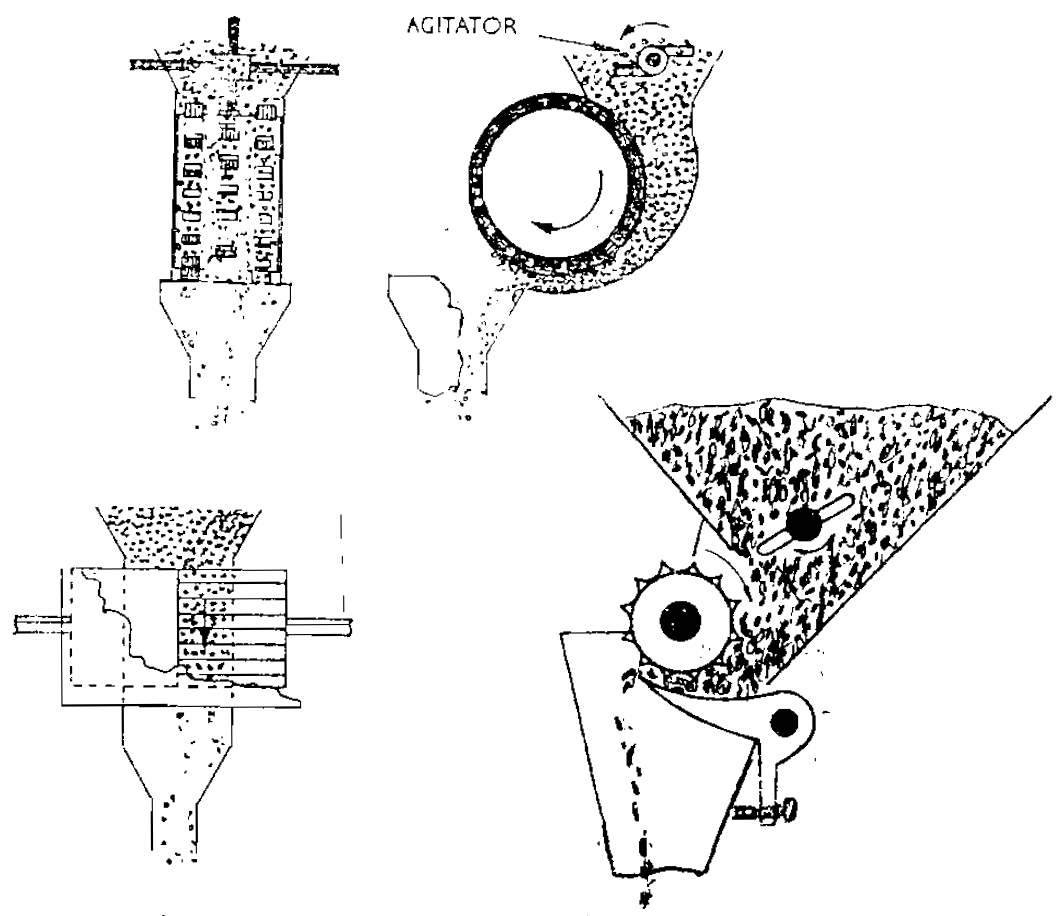

It consists of spring skewers that rotate in the direction of reverse rotation of the earth wheel (up and down). The picker picks up the feed crop from the surface of the earth and inserts it into the machine.

The lifting and lowering of the picker can be carried out to suit the nature of the soil so that the skewers do not collide with the soil surface or the obstacles present in it.

On the picker is a network of skewers that prevent the scattering of straw by wind when caught.

2. Feeding Device:

The feeder may move the straw and insert it into the press room after it has been raised to the machine by the catcher. The feeder may be a helical drum that moves the hay near the cupboard to meet a special straw that enters the straw into the cupboard. The clipper pulls the straw with it while the piston is back and when the piston moves forward, the thorns are outside the press room. The spiral cylinder can be replaced by two sets of first flakes that deliver the crop near the piston chamber to take the second set of throws by pulling it into the chamber.

3 - the pressing device

Is a piston that moves in the compression chamber (forward and backward) due to its connection to an elbow shaft that draws movement from the back shaft. There is a knife on the piston wall that works with another fixed knife located at the back of the feeding chamber. Inside the cable room for the outside.

The piston during an advance forward feeds the feed inside the cupboard. In the case of the piston back, the clipped straw falls back and falls inside the cupboard. In order to overcome this problem, many methods have been used to fix the straw inside the piston chamber when the piston is back. :

* Make the inner wall of the cupboard room is grainy and curvy and has protrusions that prevent the feed from falling back and falling while the piston is back.

* Put the crumbs on the bottom and ceiling of the cupboard room and these jaws are equipped with a swiss that will always allow them to emerge in the clipping chamber. When the piston is pressed, it presses the jaws, which leads to entering the bottom and ceiling of the clasp chamber. When the piston returns to the back, I ordered the feed and did not allow it to fall back and fall inside the room.

The feeder continues to feed and pull the crop into the piston chamber by pressing it until the feed bale exits from the outside stream at the end of the cupboard.

It is possible to control the height and width of straw bales, where there are two arms connected to the roof of the course, and through these arms can raise and reduce the outer course of the straw room, and thus control the height of straw bales, the lower the ceiling of the stream, this will reduce the height Bale straw.

The width of the bala can be controlled by pressing on both sides of the tube chamber. The lower the width of the stream, the lower the width of the straw bala.

There is a wheel called the star wheel in the roof of the outer tube of the chamber and its teeth are touched by the upper surface of the bala while pushing the piston to the straw in the chamber of the pack. This wheel is used to determine the length of the bala.

4. The contract device (shuttle):

After the straw bales are reached and reached to the specified length, which is set and determined by the star wheel, the contract device attaches the thread to a nylon, flax or sisal, and then the piston presses another ballet to push the bales that have been tied to the ground.

The process of linking the bala in three stages:

Stage 1: When the piston is ready to work, the tip of the rope outside the pulley is connected to the needle and the second end is connected to the contract device.

Stage 2: When the piston presses the straw, the hay comes out of the chamber of the clipper, carrying the cord to surround the hay bales from top to bottom and back.

Third stage: When you reach the straw machine to the specified length, the needles rise up with the pull of the end of the thread to be delivered to the contract device, which is the process of binding Bala.

Second: Circular Feeding Machine

This machine is composed of the same parts of the feed feed machine, but the press room consists of two tracks, one upper and the other lower, thus the final form of bales in the form of a cylinder.

As the straw enters the chamber, the lower walk moves and wraps around the crop inside the machine and the upper walk is equipped with a hexagon or a hydraulic cylinder that enables it to press the straw in the chamber of the capsule and the upper walkway as a result of friction and pressure on the bala. The size of the bala presses on the upper walk and when the bala reaches the size

As the straw enters the chamber, the lower walk moves and wraps around the crop inside the machine and the upper walk is equipped with a hexagon or a hydraulic cylinder that enables it to press the straw in the chamber of the capsule and the upper walkway as a result of friction and pressure on the bala. The size of the bala presses the upper wheel. When the bales reach the required size (machine controlled), they are connected to the thread that is fed with the crop inside the machine. After the binding process, the back gate of the machine is opened to push the bales outwards.

Subscribe to:

Comments (Atom)